How ERP can improve operational efficiency and reduce costs is a question that many businesses are asking. Enterprise Resource Planning (ERP) systems are powerful tools that can help organizations streamline their operations, reduce costs, and improve customer satisfaction. By integrating various business functions into a single platform, ERP systems provide a comprehensive view of an organization’s operations, enabling better decision-making and improved efficiency.

ERP systems can help businesses automate tasks, optimize resource allocation, and improve visibility across the entire organization. This can lead to significant cost savings and improved productivity. For example, ERP systems can help businesses optimize inventory management, reduce waste, and improve supply chain efficiency. They can also help businesses improve customer service by providing a single point of contact for customer interactions and facilitating faster order fulfillment.

Understanding ERP and its Impact on Operational Efficiency

An Enterprise Resource Planning (ERP) system is a software solution that integrates various business functions into a single, unified system. By centralizing data and processes, ERP systems help organizations streamline operations, reduce manual tasks, and improve decision-making.

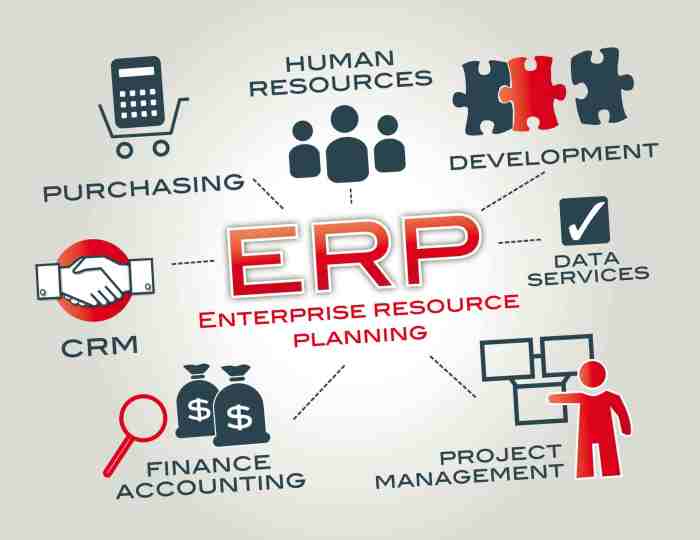

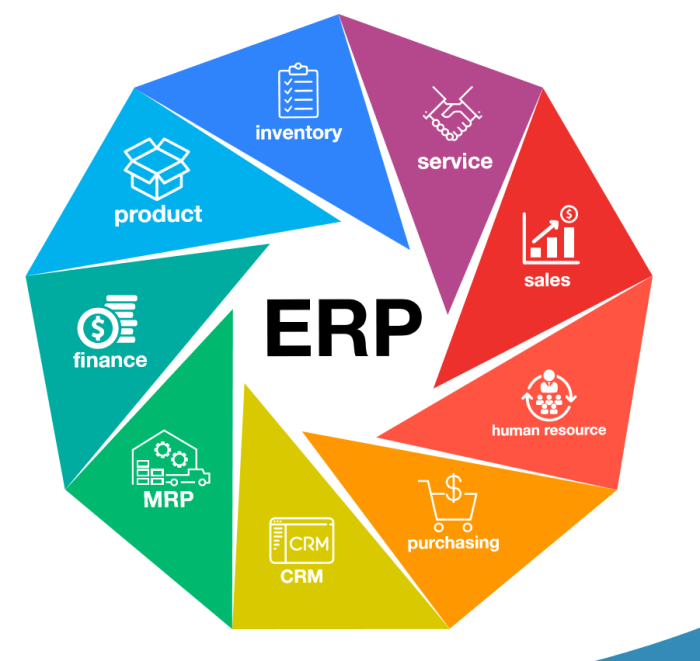

Integration of Business Functions

ERP systems act as a central hub for all core business processes, such as finance, human resources, supply chain management, and customer relationship management (CRM). They provide a unified platform for data sharing and collaboration, breaking down silos between departments and fostering greater transparency across the organization.

Streamlining Processes and Reducing Manual Tasks

ERP systems automate repetitive tasks, eliminating the need for manual data entry and reconciliation. This not only saves time and resources but also reduces the risk of errors. For example, an ERP system can automatically generate purchase orders, track inventory levels, and manage payroll.

Real-Time Data and Analytics for Improved Decision-Making

ERP systems provide real-time access to data, enabling organizations to make informed decisions based on up-to-date information. The system can analyze data and generate reports that provide insights into key performance indicators (KPIs) and identify areas for improvement. For example, a company can use ERP data to track sales trends, identify bottlenecks in the supply chain, or analyze customer behavior.

Reducing Costs through ERP Implementation: How ERP Can Improve Operational Efficiency And Reduce Costs

ERP systems can significantly reduce operational costs by streamlining processes, eliminating redundancies, and improving efficiency. By integrating various departments and functions, ERP systems provide a holistic view of operations, allowing businesses to identify and eliminate waste, optimize resource allocation, and make data-driven decisions.

Inventory Management and Waste Reduction

Effective inventory management is crucial for minimizing costs associated with storage, obsolescence, and stockouts. ERP systems offer several tools and functionalities that enable businesses to optimize inventory levels, reduce waste, and improve overall efficiency.

- Real-time Inventory Tracking: ERP systems provide real-time visibility into inventory levels, allowing businesses to monitor stock movements, identify potential shortages, and adjust production plans accordingly. This eliminates the need for manual tracking and reduces the risk of stockouts or overstocking.

- Demand Forecasting: ERP systems leverage historical data and advanced algorithms to predict future demand, enabling businesses to order the right amount of materials and avoid overstocking. Accurate demand forecasting reduces storage costs, minimizes waste, and ensures timely availability of products.

- Automated Ordering and Replenishment: ERP systems can automate the ordering process based on predefined thresholds and demand forecasts. This eliminates manual ordering errors, reduces lead times, and ensures timely replenishment of inventory.

- Inventory Optimization Tools: Some ERP systems include advanced inventory optimization tools that analyze historical data, demand patterns, and supply chain dynamics to determine optimal inventory levels for different products. These tools help businesses balance inventory costs with customer service levels.

Procurement and Supply Chain Efficiency, How ERP can improve operational efficiency and reduce costs

ERP systems play a critical role in optimizing procurement processes and improving supply chain efficiency. By integrating procurement with other business functions, ERP systems provide a comprehensive view of the supply chain, enabling businesses to streamline operations, reduce costs, and improve supplier relationships.

- Centralized Procurement: ERP systems centralize procurement activities, allowing businesses to consolidate orders, negotiate better prices with suppliers, and streamline the purchasing process. This reduces administrative overhead and ensures consistency in purchasing practices.

- Supplier Management: ERP systems facilitate efficient supplier management by providing a centralized platform for tracking supplier performance, managing contracts, and evaluating bids. This enables businesses to select the best suppliers based on factors such as price, quality, and delivery time.

- Supply Chain Visibility: ERP systems provide real-time visibility into the entire supply chain, allowing businesses to track the movement of goods, identify potential disruptions, and adjust plans accordingly. This improves supply chain responsiveness and reduces the risk of delays or stockouts.

- Automated Procurement Processes: ERP systems can automate many procurement tasks, such as purchase order generation, approval workflows, and invoice processing. This reduces manual effort, minimizes errors, and improves efficiency.

Enhanced Visibility and Control with ERP

ERP systems act as a central hub for all business data, offering a comprehensive view of operations that would otherwise be scattered across different departments and systems. This consolidated view enables better decision-making, enhanced operational efficiency, and improved control over various business functions.

Centralized View of Business Operations

ERP provides a single source of truth by integrating data from various departments, such as finance, sales, inventory, and production. This centralized view eliminates data silos and inconsistencies, enabling businesses to gain a holistic understanding of their operations.

- For instance, a sales team can access real-time inventory levels to fulfill orders accurately and promptly.

- Finance teams can track cash flow and expenses in real-time, improving financial planning and forecasting.

- Production teams can monitor production schedules and track material usage, optimizing production processes and minimizing waste.

Tracking and Reporting of Key Performance Indicators (KPIs)

ERP systems streamline the process of tracking and reporting key performance indicators (KPIs), providing valuable insights into business performance.

- Businesses can set up dashboards and reports to monitor critical metrics such as sales revenue, customer satisfaction, inventory turnover, and production efficiency.

- These dashboards offer real-time visibility into operational performance, allowing managers to identify areas for improvement and make data-driven decisions.

- For example, an ERP system can track sales conversion rates, identify top-performing products, and pinpoint customer segments with the highest purchase frequency. This information can be used to optimize sales strategies and marketing campaigns.

Improved Data Accuracy and Consistency for Informed Decision-Making

ERP systems ensure data accuracy and consistency by eliminating manual data entry and reconciliation. This improved data quality enables businesses to make informed decisions based on reliable information.

- With a centralized database, data is entered once and shared across all departments, reducing the risk of errors and inconsistencies.

- ERP systems also provide automated data validation and error checking, further enhancing data integrity.

- For example, an ERP system can automatically check if a customer’s credit limit is exceeded before processing an order, preventing potential financial risks.

Optimizing Resource Allocation and Utilization

ERP systems empower businesses to make informed decisions regarding resource allocation by providing real-time data on resource availability, utilization, and performance. This data-driven approach helps organizations allocate resources effectively, ensuring optimal utilization and minimizing waste.

Resource Utilization Comparison

The table below highlights the difference in resource utilization before and after implementing an ERP system.| Feature | Before ERP Implementation | After ERP Implementation ||—|—|—|| Resource Availability | Inaccurate and incomplete data | Real-time visibility into resource availability || Resource Utilization | Inefficient allocation leading to under or over-utilization | Optimized resource allocation based on real-time data || Resource Performance | Difficult to track and measure performance | Performance metrics tracked and analyzed for continuous improvement |

Case Study: ERP Implementation in Manufacturing

A leading manufacturing company implemented an ERP system to optimize its resource allocation. Prior to ERP implementation, the company faced challenges in accurately tracking inventory levels, leading to overstocking and understocking issues. This resulted in significant financial losses due to wasted resources and lost sales opportunities.The ERP system provided real-time visibility into inventory levels, enabling the company to forecast demand accurately and optimize its procurement process.

This led to a reduction in inventory holding costs and improved customer satisfaction. Moreover, the ERP system enabled the company to track resource utilization and identify bottlenecks in the production process. This allowed them to reallocate resources effectively, leading to increased productivity and reduced production costs.

“The ERP system has been instrumental in improving our resource allocation and utilization. We have seen a significant reduction in our inventory holding costs and an increase in our productivity. The system has also helped us to identify and address bottlenecks in our production process.”

[Company Spokesperson]

Improving Customer Service and Satisfaction

By streamlining processes and providing real-time data, ERP systems can significantly improve customer service and satisfaction.

Enhanced Customer Communication and Responsiveness

ERP systems enable businesses to centralize customer information, providing a comprehensive view of customer interactions, purchase history, and preferences. This unified platform facilitates faster and more personalized communication, allowing businesses to respond promptly to inquiries, address concerns, and proactively anticipate customer needs.

- For instance, a customer service representative can access a customer’s order history, past interactions, and any outstanding issues within the ERP system, enabling them to provide more informed and personalized support.

- Furthermore, ERP systems can integrate with communication channels such as email, chat, and social media, enabling businesses to engage with customers across multiple platforms and provide consistent service.

Facilitating Order Tracking and Fulfillment

ERP systems provide real-time visibility into order status, inventory levels, and shipping information. This transparency allows businesses to track orders efficiently, provide accurate delivery estimates, and proactively communicate any potential delays.

- Customers can access order tracking information online, providing them with peace of mind and reducing the need for inquiries.

- By automating order processing and fulfillment, ERP systems streamline the entire process, reducing lead times and ensuring faster delivery.

Personalizing Customer Experiences

ERP systems enable businesses to collect and analyze customer data, gaining insights into their preferences, purchase history, and interactions. This information can be used to personalize marketing campaigns, product recommendations, and customer service interactions.

- For example, an ERP system can identify customers who have purchased specific products in the past and recommend similar items or new releases, enhancing their shopping experience.

- By tailoring communication and offers based on individual customer profiles, businesses can create a more personalized and engaging experience, fostering stronger relationships and loyalty.

In conclusion, ERP systems offer a powerful solution for businesses looking to improve operational efficiency and reduce costs. By streamlining processes, automating tasks, and providing real-time insights, ERP systems can help businesses achieve significant improvements in their bottom line. While there may be challenges associated with ERP implementation, the potential benefits are substantial, making ERP a valuable investment for organizations of all sizes.

Commonly Asked Questions

What are the key benefits of implementing an ERP system?

The key benefits of implementing an ERP system include improved operational efficiency, reduced costs, enhanced visibility and control, automated processes, optimized resource allocation, and improved customer service.

How does ERP help improve customer service?

ERP systems can enhance customer communication and responsiveness by providing a single point of contact for customer interactions. They can also facilitate order tracking and fulfillment, leading to faster delivery times. Additionally, ERP systems can personalize customer experiences and build stronger relationships by providing insights into customer preferences and purchase history.

What are the challenges associated with ERP implementation?

Potential challenges associated with ERP implementation include data migration, system integration, user adoption, and change management. However, with proper planning, training, and communication, these challenges can be overcome.