Can ERP help my business achieve better inventory management? This question is top of mind for many businesses struggling with inefficient inventory processes. Inventory management is a critical aspect of any business, and it can be a significant source of headaches if not managed effectively. From tracking stock levels to fulfilling orders, businesses face numerous challenges in managing their inventory.

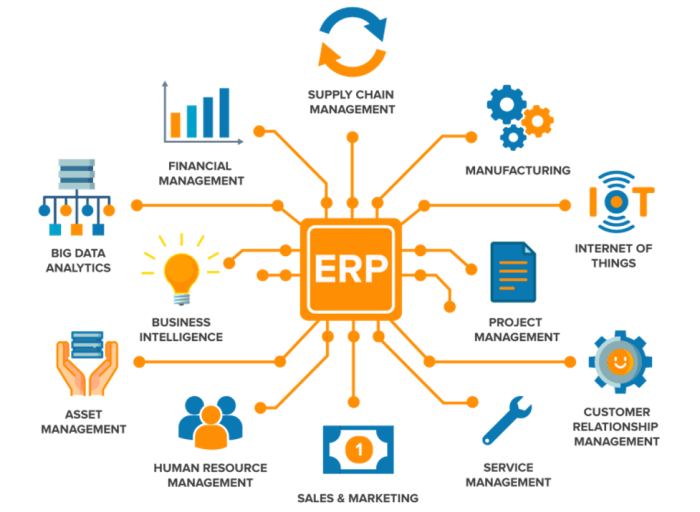

Enterprises Resource Planning (ERP) systems offer a comprehensive solution for addressing these challenges. By integrating various business functions, ERP systems provide real-time visibility into inventory levels, streamline order fulfillment, and optimize stock levels, ultimately leading to significant cost savings and improved customer satisfaction.

Understanding Inventory Management Challenges

Inventory management is a crucial aspect of any business, as it directly impacts profitability and customer satisfaction. However, managing inventory effectively can be a complex and challenging task, especially for businesses of all sizes.

Common Inventory Management Challenges, Can ERP help my business achieve better inventory management

Inefficient inventory management can lead to various challenges that can significantly impact a business’s bottom line. The following are some of the most common inventory management challenges that businesses face:

- Overstocking: Overstocking occurs when a business has more inventory on hand than it needs. This can lead to high storage costs, obsolescence, and potential damage to inventory. For example, a clothing retailer may overstock certain styles or sizes, leading to excess inventory that may not sell and eventually need to be discounted or disposed of.

- Understocking: Understocking happens when a business doesn’t have enough inventory to meet customer demand. This can result in lost sales, disappointed customers, and damage to the business’s reputation. For instance, a hardware store may run out of a popular tool during a busy season, causing customers to go elsewhere and potentially losing future sales.

- Inventory Accuracy: Inaccurate inventory records can lead to stockouts, overstocking, and difficulty in fulfilling orders. For example, if a business’s inventory records are inaccurate, they may think they have more of a particular item in stock than they actually do, leading to a stockout when a customer orders it.

- Slow Inventory Turnover: Slow inventory turnover can indicate that a business is holding onto inventory for too long. This can result in higher storage costs, obsolescence, and reduced profitability. For instance, a bookstore may have a slow inventory turnover for certain books, leading to increased storage costs and potential losses if the books become outdated.

- Poor Forecasting: Inaccurate demand forecasting can lead to overstocking or understocking. For example, if a restaurant underestimates the demand for a particular dish, they may run out of ingredients, leading to disappointed customers and lost sales.

- Supply Chain Disruptions: Supply chain disruptions can lead to delays in receiving inventory, which can disrupt production and sales. For instance, a manufacturing company may face delays in receiving raw materials due to transportation issues, leading to production delays and missed deadlines.

ERP as a Solution for Inventory Management

ERP systems are comprehensive software solutions designed to integrate and manage various aspects of a business, including inventory management. They offer a centralized platform for data storage, analysis, and control, addressing key inventory management challenges.

Core Features of ERP Systems for Inventory Control

ERP systems provide a suite of features that enhance inventory control and efficiency.

- Real-time Inventory Tracking: ERP systems provide real-time visibility into inventory levels across all locations, enabling businesses to monitor stock levels, identify potential shortages, and make informed decisions.

- Automated Inventory Management: ERP systems automate tasks such as order fulfillment, stock replenishment, and inventory adjustments, reducing manual errors and freeing up staff for more strategic tasks.

- Demand Forecasting: ERP systems use historical data and advanced algorithms to predict future demand, enabling businesses to optimize inventory levels and avoid overstocking or stockouts.

- Inventory Optimization Tools: ERP systems provide tools for inventory optimization, such as ABC analysis, which helps businesses prioritize inventory based on value and turnover, and safety stock calculations, which ensure sufficient buffer stock to meet unexpected demand fluctuations.

- Inventory Control Policies: ERP systems facilitate the implementation and enforcement of inventory control policies, such as minimum and maximum stock levels, reorder points, and lead times, ensuring consistent inventory management practices.

How ERP Modules Work Together to Optimize Inventory

ERP modules such as inventory management, purchasing, and production planning are interconnected and work together to optimize inventory levels.

- Inventory Management Module: The inventory management module tracks inventory levels, monitors stock movements, and manages stock replenishment.

- Purchasing Module: The purchasing module automates the procurement process, ensuring timely and efficient ordering of materials based on inventory requirements.

- Production Planning Module: The production planning module schedules production based on demand forecasts and available inventory, ensuring efficient utilization of resources and minimizing waste.

For example, when inventory levels fall below the reorder point, the inventory management module triggers an automated purchase order through the purchasing module. The production planning module then adjusts production schedules based on the expected arrival of new materials.

Benefits of Implementing ERP for Inventory Management

Implementing an ERP system for inventory management can significantly benefit businesses, streamlining processes, enhancing accuracy, and ultimately leading to improved profitability.

Improved Inventory Accuracy and Visibility

ERP systems provide a centralized platform for managing inventory data, offering real-time insights into stock levels, locations, and movement. This centralized approach eliminates discrepancies between physical inventory and records, leading to more accurate inventory counts.

- Real-time Tracking: ERP systems enable real-time tracking of inventory throughout the supply chain, from procurement to delivery, ensuring visibility at every stage. This eliminates delays and minimizes the risk of stockouts.

- Automated Data Entry: Automated data entry in ERP systems minimizes manual errors, ensuring data accuracy and consistency. This eliminates the need for manual reconciliation, saving time and resources.

- Centralized Database: A centralized database consolidates all inventory information, providing a single source of truth for all stakeholders. This eliminates data silos and ensures everyone is working with the same information.

Optimizing Stock Levels and Reducing Inventory Carrying Costs

ERP systems help businesses optimize stock levels by analyzing historical data and forecasting future demand. This allows businesses to maintain sufficient inventory to meet customer needs while minimizing excess stock, reducing carrying costs.

- Demand Forecasting: ERP systems use sophisticated algorithms to analyze historical sales data and predict future demand, enabling businesses to plan for anticipated fluctuations. This allows for proactive inventory management, minimizing stockouts and overstocking.

- Safety Stock Optimization: ERP systems help businesses determine the optimal safety stock levels, ensuring sufficient inventory to cover unexpected demand fluctuations. This reduces the risk of stockouts while minimizing excess inventory.

- Inventory Turnover Analysis: ERP systems provide insights into inventory turnover rates, helping businesses identify slow-moving items and adjust inventory levels accordingly. This optimizes inventory flow and reduces holding costs.

Streamlining Order Fulfillment Processes and Improving Customer Satisfaction

ERP systems streamline order fulfillment processes by automating tasks and providing real-time visibility into order status. This allows businesses to fulfill orders faster and more efficiently, leading to improved customer satisfaction.

- Automated Order Processing: ERP systems automate order processing, reducing manual errors and expediting the fulfillment process. This ensures orders are processed accurately and efficiently, minimizing delays and improving customer satisfaction.

- Real-time Order Tracking: Customers can track their orders in real-time through the ERP system, providing transparency and enhancing communication. This keeps customers informed and reduces inquiries, improving their overall experience.

- Improved Inventory Allocation: ERP systems enable efficient inventory allocation, ensuring that orders are fulfilled from the most appropriate location, minimizing shipping costs and delivery times. This optimizes order fulfillment and enhances customer satisfaction.

Key Features of ERP for Inventory Management

ERP systems are designed to integrate various business functions, including inventory management. Their comprehensive approach enables businesses to streamline processes, improve efficiency, and gain valuable insights into their inventory.

Real-Time Inventory Tracking

Real-time inventory tracking is crucial for accurate and up-to-date information on inventory levels. This feature allows businesses to monitor stock in real-time, providing a clear view of available inventory across all locations.

Real-time inventory tracking enables businesses to make informed decisions about purchasing, production, and fulfillment.

Automated Purchase Orders

Automated purchase order generation streamlines the procurement process. ERP systems can automatically generate purchase orders based on predefined criteria, such as minimum stock levels or forecasted demand.

Automated purchase orders reduce manual errors, save time, and improve efficiency in the procurement process.

Demand Forecasting

Demand forecasting tools help businesses predict future demand based on historical data and market trends. This feature allows for better planning and optimization of inventory levels.

Demand forecasting enables businesses to anticipate fluctuations in demand and adjust their inventory accordingly.

Inventory Optimization Tools

Inventory optimization tools help businesses determine the optimal inventory levels for each product. These tools consider factors such as demand, lead times, and storage costs to minimize inventory holding costs and stockouts.

Inventory optimization tools help businesses strike a balance between meeting customer demand and minimizing inventory costs.

Warehouse Management Capabilities

Warehouse management capabilities provide a centralized platform for managing warehouse operations, including receiving, storing, and shipping inventory. This feature helps businesses optimize warehouse space utilization and improve efficiency.

Warehouse management capabilities streamline warehouse operations, reduce errors, and improve overall efficiency.

Reporting and Analytics

Reporting and analytics tools provide businesses with comprehensive insights into their inventory performance. These tools generate reports on key metrics such as inventory turnover, stockouts, and fulfillment rates.

Reporting and analytics tools enable businesses to identify areas for improvement and make data-driven decisions to optimize their inventory management.

Considerations for Choosing an ERP System

Choosing the right ERP system is crucial for successful inventory management. A poorly chosen system can lead to inefficiencies, errors, and ultimately, lost revenue. This section explores key factors to consider when selecting an ERP system for inventory management, allowing you to make an informed decision.

Factors to Consider

When choosing an ERP system for inventory management, several key factors should be considered. These factors will help you narrow down your options and select a system that best meets your specific needs.

- Business Size and Complexity: ERP systems come in various sizes and complexities. Smaller businesses may benefit from a cloud-based ERP solution that is easy to implement and manage. Larger, more complex businesses may require an on-premises solution with more robust features and scalability. Consider your current and future needs when assessing the size and complexity of the ERP system.

- Industry-Specific Needs: Different industries have unique inventory management requirements. For example, a manufacturing company may need an ERP system with advanced production planning and scheduling capabilities, while a retail company may need an ERP system with strong point-of-sale integration. Choose an ERP system that caters to the specific needs of your industry.

- Budget: ERP systems can vary significantly in price. It’s important to establish a budget before you start shopping around. Consider factors like implementation costs, ongoing maintenance fees, and the cost of training your staff. Choose a system that fits within your budget while offering the necessary features and functionalities.

- Scalability and Flexibility: Your business needs may change over time. Choose an ERP system that is scalable and flexible enough to accommodate your future growth. This ensures that the system can handle increasing volumes of data and transactions as your business expands.

- Integration with Existing Systems: Your business likely uses various existing systems, such as accounting software, customer relationship management (CRM) systems, and e-commerce platforms. Choose an ERP system that can seamlessly integrate with your existing systems to avoid data silos and ensure data consistency.

- User Interface and Ease of Use: The user interface of an ERP system should be intuitive and easy to use for your employees. A user-friendly interface will help minimize training time and ensure that employees can easily navigate the system and access the information they need.

- Vendor Support and Training: Look for an ERP vendor that provides excellent customer support and training. This ensures that you can get help when you need it and that your employees are properly trained to use the system effectively.

Comparing ERP Solutions

Once you have identified your needs, you can start comparing different ERP solutions. Here are some key factors to consider when evaluating different ERP solutions:

- Inventory Management Capabilities: Assess the inventory management capabilities of each ERP solution. Look for features such as real-time inventory tracking, demand forecasting, inventory optimization, and automated purchase order generation. Compare the capabilities of different systems and choose the one that best aligns with your specific needs.

- Reporting and Analytics: An ERP system should provide comprehensive reporting and analytics capabilities. This allows you to gain insights into your inventory performance, identify areas for improvement, and make informed decisions. Compare the reporting and analytics capabilities of different systems and choose the one that offers the most relevant and actionable insights for your business.

- Mobile Accessibility: Consider the mobile accessibility of the ERP solution. A mobile-friendly system allows your employees to access inventory data and perform tasks from anywhere, anytime. This can be particularly beneficial for businesses with mobile workforces or those that need to track inventory in real-time.

- Security and Compliance: Data security and compliance are critical considerations for any ERP system. Choose a system that meets your security and compliance requirements and has robust measures in place to protect your sensitive data.

Key Functionalities for Inventory Management

The specific functionalities you need from an ERP system will depend on your business’s unique needs. However, some key functionalities are essential for effective inventory management:

- Real-time Inventory Tracking: Real-time inventory tracking provides a clear and accurate view of your inventory levels at all times. This allows you to make informed decisions about ordering, production, and distribution.

- Demand Forecasting: Demand forecasting helps you predict future demand for your products. This information allows you to optimize inventory levels and avoid stockouts or overstocking.

- Inventory Optimization: Inventory optimization tools help you minimize inventory costs while maintaining adequate inventory levels. These tools use algorithms to analyze historical data and predict future demand, allowing you to optimize your inventory levels and reduce holding costs.

- Automated Purchase Order Generation: Automated purchase order generation streamlines the procurement process. The system can automatically generate purchase orders based on predefined rules and thresholds, reducing manual effort and errors.

- Warehouse Management: Warehouse management features help you manage your warehouse operations efficiently. These features include functions such as receiving, put-away, picking, packing, and shipping. They can also track inventory movements within the warehouse and provide real-time visibility into inventory locations.

- Lot and Serial Number Tracking: For businesses that handle products with lot or serial numbers, the ERP system should have features to track these numbers. This allows you to manage inventory traceability and ensure compliance with regulations.

Implementing ERP for Inventory Management: Can ERP Help My Business Achieve Better Inventory Management

Implementing an ERP system for inventory management can be a complex process, but it offers significant benefits for businesses. A well-planned and executed implementation strategy is crucial for maximizing the return on investment.

Steps Involved in Implementing an ERP System for Inventory Management

The implementation process typically involves several stages:

- Planning and Scoping: This stage involves defining the project goals, identifying the scope of the implementation, and establishing a project team. It’s crucial to have a clear understanding of the business requirements and objectives for inventory management.

- Data Migration: This stage involves transferring existing inventory data from legacy systems to the new ERP system. Data accuracy and completeness are essential for the successful functioning of the ERP system.

- System Configuration: The ERP system needs to be configured to meet the specific needs of the business. This involves setting up modules, defining workflows, and customizing reports.

- User Training: It’s crucial to provide comprehensive training to users on how to use the new ERP system effectively. Training should cover all aspects of the system, including data entry, reporting, and troubleshooting.

- Testing and Go-Live: Before the system goes live, it’s essential to conduct thorough testing to ensure that all functionalities work as expected. This includes testing data integrity, system performance, and user experience.

- Post-Implementation Support: Ongoing support is essential to ensure that the ERP system continues to meet the evolving needs of the business. This includes providing technical support, resolving issues, and making necessary updates.

Challenges and Considerations During Implementation

Implementing an ERP system can present several challenges:

- Data Integration: Integrating data from multiple legacy systems can be a complex and time-consuming process. Ensuring data accuracy and consistency is crucial.

- User Adoption: Resistance to change can be a significant challenge. It’s essential to address user concerns and provide adequate training to encourage adoption.

- Customization: While customization can be beneficial, it can also add complexity and increase implementation costs. It’s essential to strike a balance between customization and standardization.

- Project Management: Implementing an ERP system requires careful project management to ensure that the project stays on track and within budget.

Best Practices for Ensuring a Successful ERP Implementation

To maximize the chances of a successful implementation, consider these best practices:

- Define Clear Goals and Objectives: Clearly define the business goals and objectives for implementing the ERP system. This will help ensure that the implementation aligns with the overall business strategy.

- Involve Key Stakeholders: Involve key stakeholders from all departments in the implementation process. This will help ensure that the system meets the needs of the entire organization.

- Choose the Right ERP System: Select an ERP system that is tailored to the specific needs of the business. Consider factors such as industry-specific features, scalability, and integration capabilities.

- Develop a Comprehensive Implementation Plan: Create a detailed implementation plan that Artikels all stages of the process, including timelines, resources, and responsibilities.

- Provide Adequate Training: Ensure that all users receive adequate training on how to use the new ERP system effectively. This will help minimize resistance to change and ensure that the system is used correctly.

- Conduct Thorough Testing: Conduct thorough testing before going live to ensure that the system works as expected. This will help identify and resolve any issues before they impact the business.

- Monitor and Evaluate: Regularly monitor the performance of the ERP system and evaluate its impact on the business. This will help identify areas for improvement and ensure that the system continues to meet the evolving needs of the organization.

Measuring the Impact of ERP on Inventory Management

It’s crucial to track and measure the impact of ERP on inventory management performance to ensure that the investment is yielding positive results. This involves identifying key metrics, analyzing data, and identifying areas for improvement.

Key Metrics for Monitoring Inventory Management Performance

Tracking key metrics provides insights into the effectiveness of inventory management strategies.

- Inventory Turnover Rate: This metric indicates how efficiently inventory is being used. It is calculated by dividing the cost of goods sold by the average inventory value. A higher turnover rate suggests efficient inventory management.

- Fill Rate: This metric measures the percentage of customer orders that are fulfilled on time and in full. A higher fill rate indicates better inventory availability and customer satisfaction.

- Lead Time: This metric represents the time it takes to receive inventory from the supplier to the warehouse. Shorter lead times allow for better responsiveness to customer demand.

- Inventory Accuracy: This metric reflects the accuracy of inventory records. High accuracy minimizes stockouts and ensures that the right amount of inventory is available.

- Inventory Holding Costs: This metric captures the costs associated with storing inventory, including warehouse space, insurance, and obsolescence. Lower holding costs indicate efficient inventory management.

Analyzing Data to Identify Areas for Improvement

Analyzing data from these key metrics can reveal opportunities for improvement.

- Trends in Inventory Turnover Rate: A declining inventory turnover rate might indicate excessive inventory or slow-moving items. This suggests a need to optimize inventory levels and potentially adjust purchasing strategies.

- Fill Rate Fluctuations: Significant drops in fill rate may signal problems with inventory availability, forecasting, or supplier reliability. Analyzing these fluctuations can pinpoint the root causes and guide corrective actions.

- Lead Time Variations: Inconsistent lead times can disrupt production schedules and lead to delays in fulfilling customer orders. Analyzing lead time variations can identify bottlenecks in the supply chain and suggest ways to improve efficiency.

- Inventory Accuracy Discrepancies: High levels of inventory discrepancies indicate inaccurate records, which can lead to stockouts, overstocking, and increased costs. Addressing these discrepancies is essential for effective inventory management.

- Inventory Holding Cost Trends: Rising inventory holding costs can indicate inefficiencies in storage, handling, or inventory management processes. Analyzing these trends can reveal opportunities to optimize storage space, improve handling practices, and reduce overall costs.

Implementing an ERP system can be a game-changer for businesses seeking to optimize their inventory management processes. By providing a centralized platform for managing inventory, ERP systems empower businesses to gain better control over their supply chain, reduce costs, and enhance customer satisfaction. The benefits of ERP for inventory management are undeniable, and businesses of all sizes can reap the rewards of adopting this powerful solution.

Questions and Answers

What are the key benefits of using an ERP system for inventory management?

ERP systems offer several benefits, including improved inventory accuracy, reduced stock levels, streamlined order fulfillment, enhanced visibility into inventory data, and better forecasting capabilities.

How can I choose the right ERP system for my business?

When selecting an ERP system, consider your specific business needs, industry, budget, and the functionalities offered by different ERP solutions. It’s crucial to evaluate the inventory management capabilities of each system and ensure it aligns with your requirements.

What are the common challenges associated with implementing an ERP system?

Implementing an ERP system can present challenges such as data migration, system integration, user training, and change management. It’s essential to have a well-defined implementation plan, address potential challenges proactively, and involve key stakeholders throughout the process.